Aerospace firm outlines plan to scale operations

STREAMLINED PRODUCTION By performing in-house testing, Dragonfly Aerospace can optimise their workflow, reduce development timelines, and facilitate serial production of their imaging satellites

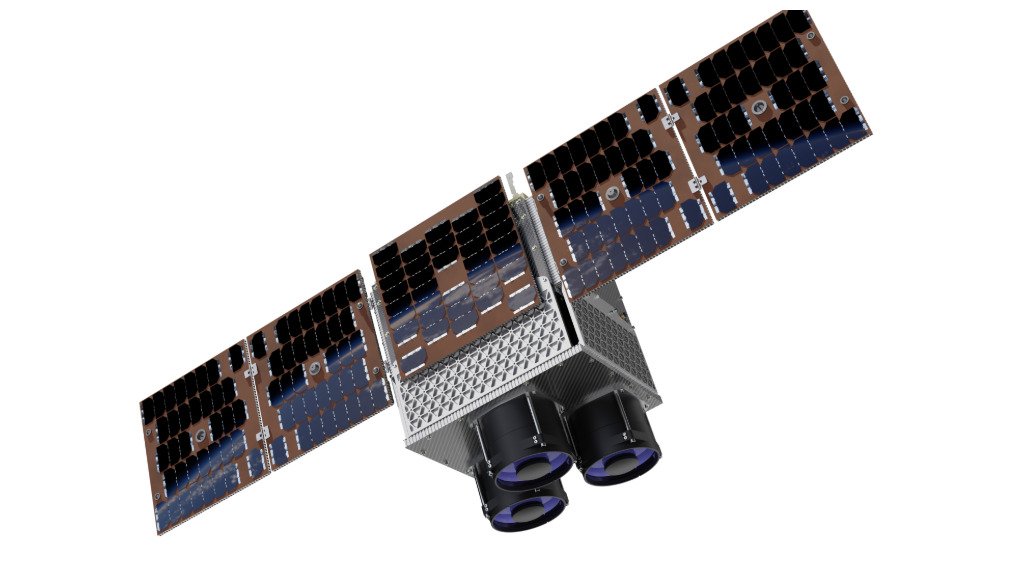

HIGH PERFORMANCE Dragonfly Aerospace satellite buses are engineered to support powerful payloads such as electro-optical systems, delivering high-quality, wide-spectrum Earth observation data

Stellenbosch-headquartered aerospace company Dragonfly Aerospace is optimised for high-tech manufacturing with its 3 000 m2 facility, which also includes 1 000 m2 of dedicated cleanroom space, allowing it to design, manufacture and test satellite buses and payloads on-site.

By controlling the entire process, from component production through to final assembly, the company can ensure high quality, reduce costs, and accelerate the delivery of its products, says Dragonfly Aerospace CEO Bryan Dean.

Dragonfly is currently developing the more compact 50 kg ηDragonfly bus to make high- quality Earth observation even more accessible and affordable for a new generation of missions that need to collect high-resolution imagery and data for applications such as precision agriculture and environmental monitoring.

This bus uses the same flight-proven avionics and power systems on the µDragonfly system and is expected to be fully certified by the end of 2025, thereby enabling the company to offer cost-effective, high-performance solutions for customers who need to scale their Earth observation capabilities. The ηDragonfly bus is also designed to be launched in batches of four from a SpaceX Falcon 9 port in the US.

Regarding its imaging payloads, Dragonfly Aerospace is scaling up its production capacity for hyperspectral and shortwave infrared cameras to support constellation orders.

“We manufacture our own satellite components with a ‘Buy What We Fly’ philosophy, meaning the components we offer to customers are the same as those currently operating reliably in orbit on EOS Data Analytics’ first satellite (EOSSAT-1), which has now been in orbit for two-and-a-half years,” Dean says.

In-House Capability

Dragonfly Aerospace manufactures and tests a range of flight-proven satellite components in-house, used both in its satellites and by external customers, and all have achieved Technology Readiness Level 9, or TRL 9, thereby demonstrating successful operation in space.

“Our component offerings include the EPS-LP power system, 28 V battery module, and RW-1Nms reaction wheel, on-board computer, as well as key communications systems such as the X-Band high-data-rate transmitter, or HDRTx, and the S-Band command transceiver, or CTR-S,” says Dean.

To further reduce risks, Dean highlights that the company collaborates with leading organisations in space debris monitoring and alert systems, enabling effective collision avoidance planning. Additionally, Dragonfly Aerospace is advancing its attitude control capabilities by experimenting with moon and star imaging using EOSSAT-1, validating the precision of its µDragonfly bus platform to conduct near-Earth imaging with line-scan imagers.

The µDragonfly bus has a compact form factor to accommodate large optical payloads and has been designed to allow three µDragonfly satellites to be launched in a cluster in a 2.2-m payload fairing, making it suitable for serial production and large-scale deployment. As most satellite bus components are manufactured and tested in-house, it is also cost-effective, which is a critical factor for building large, affordable satellite constellations.

In terms of high-volume data collection, the bus is equipped with a “highly capable power system” that can support a large amount of imaging and data downlinking during each orbit. This ensures the satellite can perform its primary function of data collection effectively. It also includes high-data-rate transmitters, enabling the quick and efficient downloading of large volumes of image data captured daily. This feature is crucial for missions that rely on rapid data delivery.

Diverse Applications

Beyond agriculture, Dragonfly Aerospace CEO of Cameras Francois Mostert highlights that hyperspectral imaging plays a vital role in tracking vegetation and environmental change, as it can distinguish plant species, monitor biodiversity and detect stress in ecosystems, while also identifying deforestation or land-use changes.

By measuring vegetation density, biomass and forest cover loss, the imagery provides insights into how much carbon is being absorbed or released into the atmosphere. This helps identify carbon sinks, monitor emissions from land degradation and guide strategies for climate action and sustainable land management.

Additionally, in pollution monitoring, hyperspectral sensors help assess water quality, detect chemical or biological contaminants and track soil and air pollution. Together, these applications make hyperspectral imaging a powerful tool for sustainable resource management and environmental protection.

“Hyperspectral imaging captures data across hundreds of narrow spectral bands, providing detailed insights. In agriculture, this technology is used to monitor crop health, identify stress from pests, disease or drought, and improve yield prediction,” Mostert says.

Analysing spectral signatures reflected from plants enables monitoring of characteristics such as chlorophyll, water content and leaf structure which, in turn, helps farmers optimise resources such as water, fertiliser and pesticides.

Dragonfly Aerospace will continue to focus on the compactness, performance and affordability of its imaging payloads and satellite products to provide a variety of applications, from sustainable resource management to disaster response.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation